- Home

- Products

-

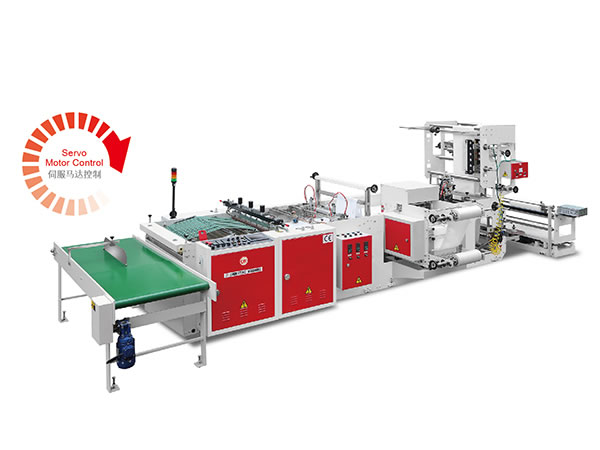

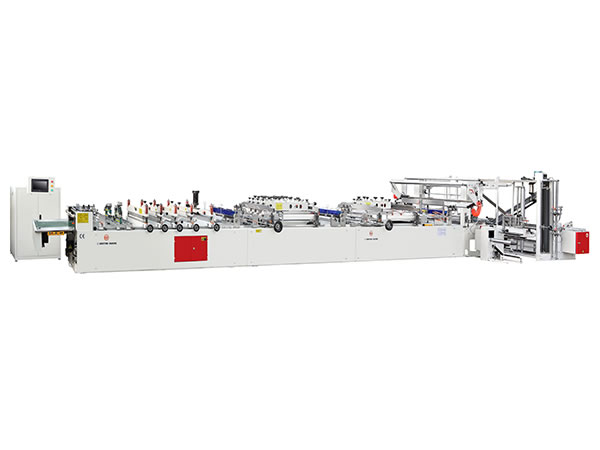

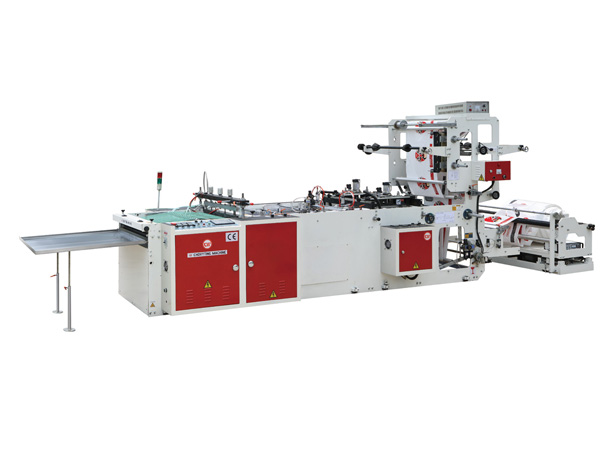

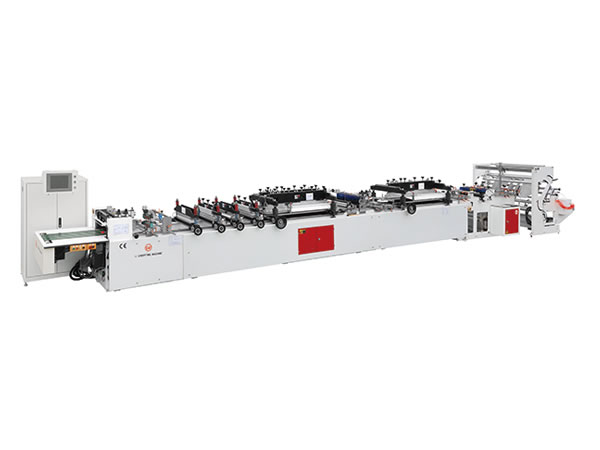

- CW-800CSD Super High Speed Soft Loop Handle Bag Making Machine

1. 3 pcs servo motor drive from soft loop handle device. (Patent)

2. The new design of bag stack and speed down conveyor system. (Patent)

3. Special design of turnover side sealing knife (Italy system)

-

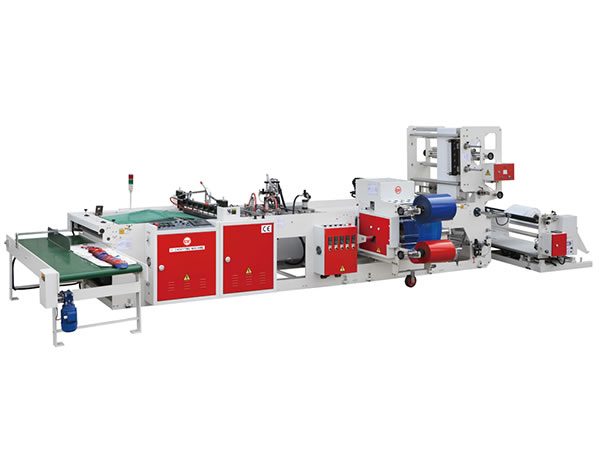

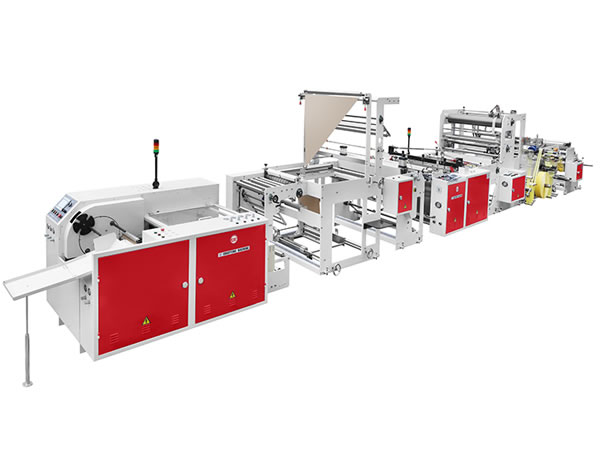

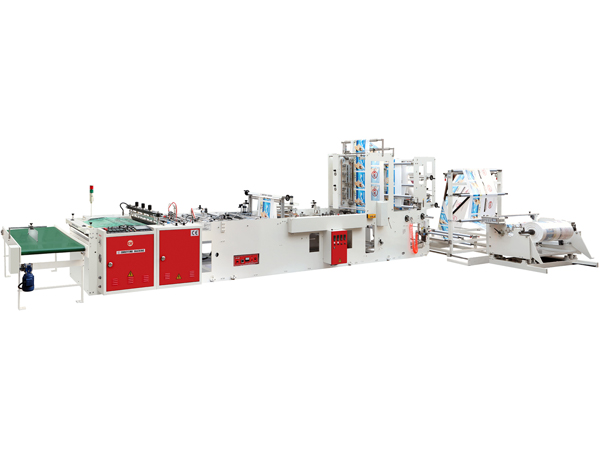

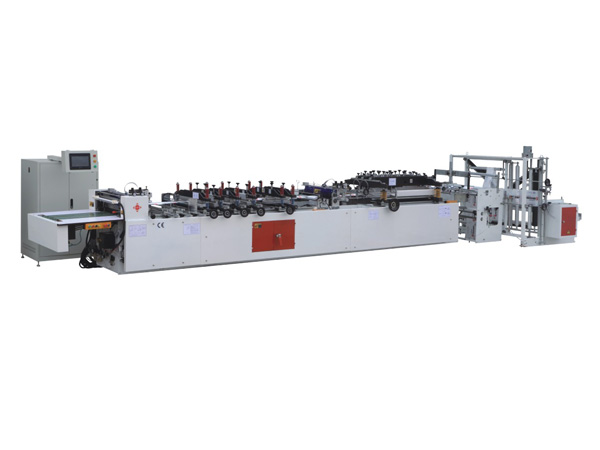

- CW-800SP Fully Automatic Patch Handle Bag Making Machine

1. With servo motor drive, PLC and touch screen control

2. Machine frame is made of prefabricated flame cut sheet 12mm thick to ensure the machine rigidity.

3. Any different type of the bag with several use as options, easy to replace

-

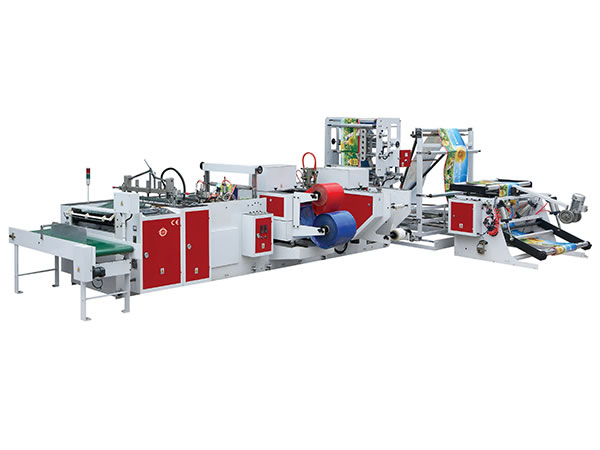

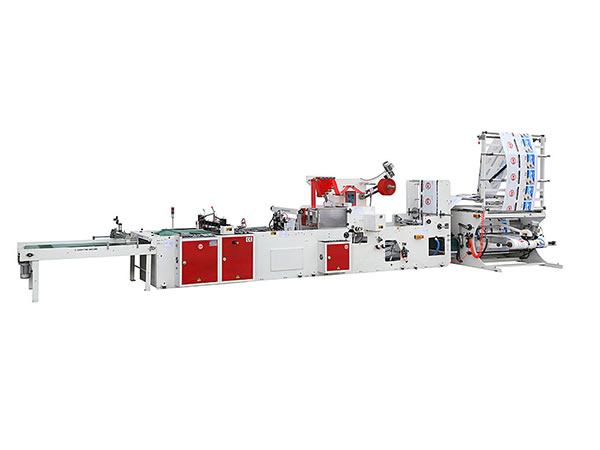

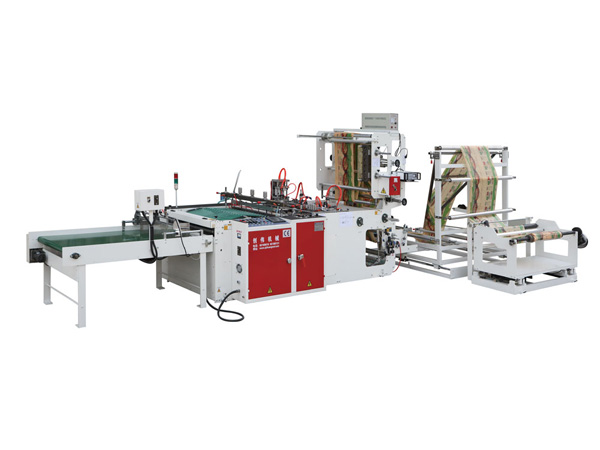

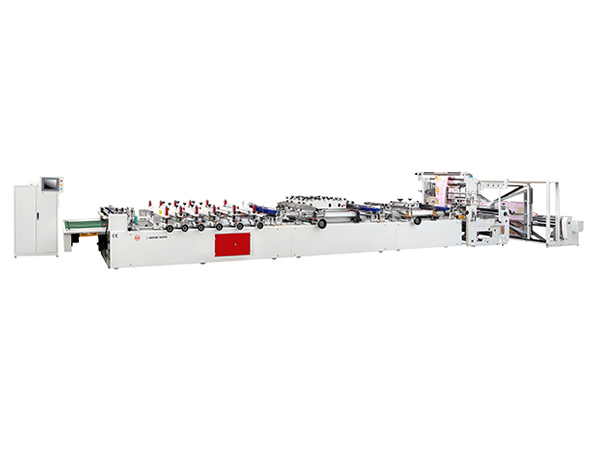

- CW-800SDP High Speed Handle Bag Making Machine

1. The design of soft loop handle and patch handle in the same side, fast exchange the type of bag

2. Soft loop handle device with 3 pcs servo motor drive (Patent)

3. The rotary device of patch handle is driven by servo motor. (Patent)

-

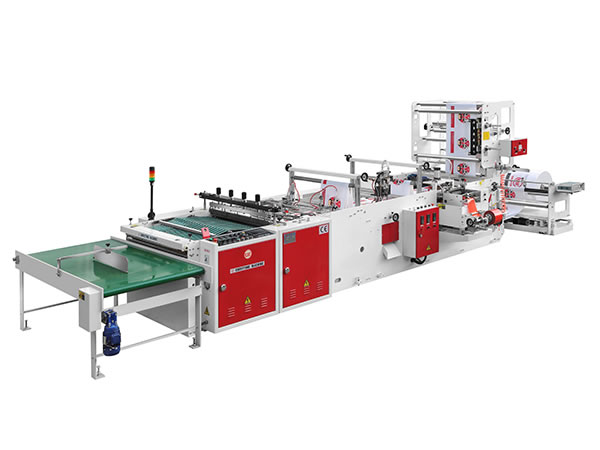

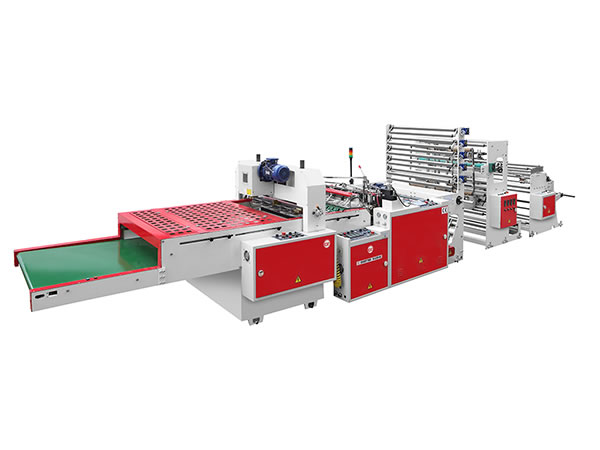

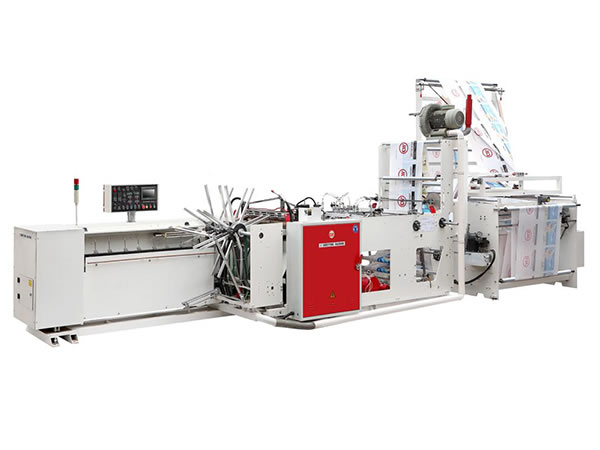

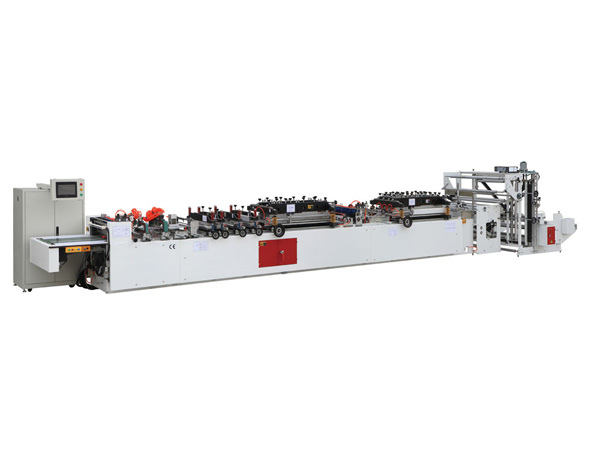

- CW-800LP Fully Automatic Soft Loop Handle Bag Making Machine

1. With servo motor drive, PLC and touch screen control

2. Machine frame is made of prefabricated flame cut sheet 12mm thick to ensure the machine rigidity.

3. Any different type of the bag with several uses as options, easy to replace

-

- CW-1000SW Fully Automatic Sine Wave Cutter Bag Making Machine

1. CHOVYTING is the only one manufacturer for sine wave bag machine in Asia area.

2. Autonomic controlled by PLC and touch screen for bag width and sine wave

3. With handle punching device

-

- CWZD-C+CS Series Heavy Duty Multifunction Laminated Doypack Bag Making Machine

1. It is multi-function machine, to make zipper stand up bags (doypack), 3 side sealing bag and center sealing bag.

2. Large human-computer interface screen control, automatic design and PLC control.

3. Heavy-duty heat sealing structure will get stronger sealing.

-

- CW-1000PG+OR Automatic Bags on Roll Making Machine (Bags with Ribbon)

1. This machine is to make both overlap and perforation rolling bag.

2. Rewinder with 4 servo motor control

3. Chovyting is the only one manufacturer for this equipment in China.

-

- CW-800NJT Patch Handle Carrier Bag Making Machine

1. From gluing, slitting, cutting to sticking, it accomplishes with high speed automatically and in one run. (Patent)

2. Special pattern preheat knife for enhanced sealing hardness

3. Turnover heavy-duty sealing knife seat, easy to clean.

-

- CW-800ZD Plastic Carrier Bag Making Machine

1. This machine is to make soft loop handle bag, patch handle bag, poly draw handle bag, and die cut handle bag

2. Pre-sealing knife, heated on double sides and strong for fusing, to make the bags without deformation.

3. The best quality of Italian design side sealing knife, heated to high temperatures without deformation.

-

- CW-800SBD,CW-1000SBD Side Weld Bag, Bottom Weld Bag Making Machine

1. Heavy-duty frame design, less machine vibration under high-speed running

2. Special sealing blade design, exchange quickly and easily

3. Feeding motor automatic control, trouble-free operation.

-

- CW-1000BSDS High Speed Bag Making Machine (Single/Double Line Side Seal and Bottom Seal Bag)

Brief Introduction CW-1000BSDS high speed bag making machine is used for making single and double line printed bag. This bag maker has multi-functions on the basis of new design conception.

-

- CW-1100BS5+AP High Speed Calendar Bag Making Machine

CW-1100BS5+AP high speed calendar bag making machine is equipped with automatic punch press and servo driving system.

-

- CW-500ZD Bottom Seal Soft Loop Handle Bag Making Machine

1. Combined with bag forming and loop handle attaching device in one single machine, to replace semi-automatic soft loop handle sealing machine.

2. V-type sealing for both side gusset of the bag

3. With automatic conveyor table to deliver the finished bags while it is counted.

-

- CW-800SBD+DHL Multi-Function Bag Making Machine

The multifunction bag making machine boasts heavy duty, multiple functions, high speed as well as great output. It is primarily used for mailing bag and postal bag making.

-

- CW-800SBD+ ZP Zipper Bag Making Machine

This range of zipper bag making machine is multifunctional, and it is most frequently utilized for making diaper bags. It is especially designed with a plastic zipper device, and a puncher for making baby diaper bags with 2 holes on the top. This product has been very popular in Columbia, Venezuela as well as other countries.

-

- CW-800RS+CK Side Seal Bag Making Machine

The side sealing bag making machine is characterized by full automation and heavy duty. As an economical plastic bag making device, it integrates bag sealing function. The product is normally used to manufacture side sealing PE bags with two specially punched holes for hanging use.

-

- CW-800BFS Perforated Bag Making Machine

1. This is a special equipment to make chicken bag and bread bag at high speed 250pcs/min

2. Servo motor driving and Germany Sick photocell

3. Rotary-arms unit for collection of bags (Patent)

-

- CW-1400FB High Speed Bottom Seal Bag Making Machine with Fly Knife System

Heavy duty bottom seal bag making machine is specialized in producing bags with high thickness.

-

- CW-1000PR+C2 Bag Roll Making Machine

The plastic bag maker has long sealing time while requiring low temperature so that seals can not be destroyed and the bag can be high quality guaranteed. Additionally, the sealing system can continuously feed materials using the swinging principle. This design has gained relevant patent.

-

- CW-300V2/ CW-400V2 Vest Carrier Bag Making Machine

Hot sealing/cutting type (for strong bottom welding)

Material: HDPE, LDPE, Recycled material, CaCO3 added (to save material cost)

Tube film with or without gusset on both sides can be processed by this t-shirt bag making machine.

-

- CWZD-400-A, CWZD-500-A,CWZD-600-A Side Seal Bag Making Machine

This range of side sealing bag making machine is multifunctional, and is mainly used to make various composite film materials into multifunctional laminated bags, like three side sealing bag, central sealing bag, central sealing bag with side gusset, four side sealing bag, five side sealing bag, etc. Also, it can be used for making stand-up pouch, zipper bag, and more.

-

- CWZD-400B,CWZD-500B,CWZD-600B Laminated Bag Making Machine

The laminated bag making machine has heavy duty and multiple functions. It is applied to a variety of laminated films to manufacture composite bags including three side sealing type, central sealing type, central sealing with side gusset type, four side sealing type, five side sealing type, stand-up pouch, zipper bag and so on.

-

- CWZD-400B+FS,CWZD-500B+FS,CWZD-600B+FS Side Seal Bag Making Machine

The laminated bag making machine, featuring heavy duty and multiple functions, is an economical type applicable to make various kinds of composite film into laminated bags. It is impossible for one unit to make all kinds of bags. Therefore, we produce laminated bag making machines of different models for variable sorts of bags. This product is great for three side sealing bag, central sealing bag, central sealing bag with side gusset, four side sealing bag ...

-

- CWZD-400B+FD, CWZD-500B+FD,CWZD-600B+FD Laminated Bag Making Machine

Unlike the CWZD-B model, this range of bag making equipment can make two kinds of stand-up bags. One is made by cutting the bottom and an extra sheet of unprinted film is heat sealed on the bottom. The other comes into being by folding a single sheet film into the bottom without cutting the bottom.

-

- CWZD-400-ZF High Speed Bag Making Machine Specially Used for Center and Bottom Sealing Bag (Center Seal Bag and Four Side Seal Bag Making Machine)

It is able to change the bag making type easily from center sealing to four side sealing bag for ease of operation. Double servo motor, double inverter driving, the film will not shake even when the machine runs at a high speed.

-

- CW-500HSC,CW-700HSC Heat Sealing Vest Carrier Bag Making Machine

Since two ends of the bag mouth are heat sealed, the product should be fitted with CWX626-8T mechanical punching device to add the handle to the bag.

-

- CP-400HSC/2, CP-300HSC/2 Plastic Shopping Bag Making Machine

Dissimilar to the CW-500HSC model, this product uses double servo motors and dual photocell tracking systems to make two lines of printed or unprinted plastic carrier bags.

-

- CW-300NT2, CW-400NT2 Plastic Vest Carrier Bag Making Machine

It comes with 2 stepper motors and relevant driving system for material transmission. The shopping bag making equipment can also be configured with Japanese servo motor and corresponding driving system. Additionally, the driving system is subject to the regulation of a single chip microcomputer.

-

- CW-600 BSC, CW-1000 BSC Bottom Weld Bag Making Machine

The bottom sealing bag making equipment comes with one set of stepper motor and driver. With one photocell tracking system, it is great for both printed and unprinted bags. The different types of bottom weld bag made by this product can be commonly seen in supermarkets, department stores, etc.

-

- CP-400BSC-4L Garbage Bag Making Machine

Same as the CW-BSC model, this series of garbage bag making machine is available with heat sealing and cold cutting functions, and is great for making bottom sealing bags. It is a good choice for two layers and four lines of non-printed bags. Equipped with one stepper motor and a photocell, the product makes only one line of the printed bag.

-

- CP-500RT, CP-700RT Trash Bag Roll Making Machine

The trash bag roll making machine is fully automatic and is mainly applied to make bottom sealing garbage bag on roll. When equipped with vest punching blade, it is also workable for vest type garbage bag on roll. The center of finished bag on roll can be fitted with or without the paper core.

-

- CP-600RDL, PC-800RDL Side Sealing Plastic Bag Making Machine

The side sealing plastic bag making machine is computer controlled and is especially suitable for manufacture of PE and OPP side sealing bags. It can be optionally equipped with the punching equipment to serve as plastic handle bag making equipment. This product is available in various models in accordance with different lengthes of the bags.

-

- CP-1400FD, CP-1600FD Film Rewinding Machine

The former is primarily used for folding a single film, and is suitable for all types of side sealing bag making units. The rewinding unit comes with the ultrasonic and EPC system. Together with the CW-RDL side sealing bag maker, this plastic film rewinding machine is a good solution to OPP header card bag which can pack stationery, socks, clothes, etc.

-

- CP-SH Soft Loop Handle Welding Machine

The side or bottom sealing bags should be manually placed under the sealing knife with a weld handle. Then, the bottom of the motor is pressed with the foot for heat sealing of the handle. Based on such a process, the operation speed of the carrier bag handle sealing machine is not so fast, normally 20 to 30 pieces per minute.

-

- Rotary Die Head Blown Film Line

The rotary die head blown film line mainly works to blow a variety of plastic laminated films made of LDPE, HDPE as well as LLDPE. These PE films are widely employed as raw materials to make packaging bags for liquid, printing substrate, export product, industrial product, and so on.

-

- Co-Extrusion Blown Film Line

The plastic film blowing machine comes with two sets of screw and barrel, as well as two sets of die head and gear boxes. The screw is constructed from 38CRMOAIA alloy steel with precision machining and nitrogen treatment. Accordingly, it has optimum hardness and can be used durably.

-

- High Speed Flexographic Printer

The heavy duty frame design of the product can make the noise and vibration at the minimal level during high speed operation. The stable tension control system and color registering accuracy are good indicators of printing effects and qualities.

-

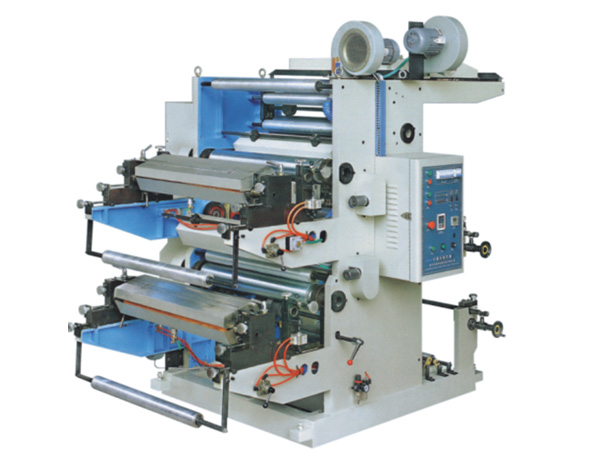

- Standard Flexographic Printer

The printing plate cylinder allows for manual lifting and lowering, as well as offers automatic stirring of the printing ink after being lifted. The flexo printing machine can be optionally equipped with EPC system plus magnetic powder device for winding and unwinding tension control. It is suitable for various reel shaped packing materials, such as BOPP, PE, paper, etc., and is a preferred choice for food paper packaging, supermarket handbag, T-shirt bag, cloth bag, etc.

-

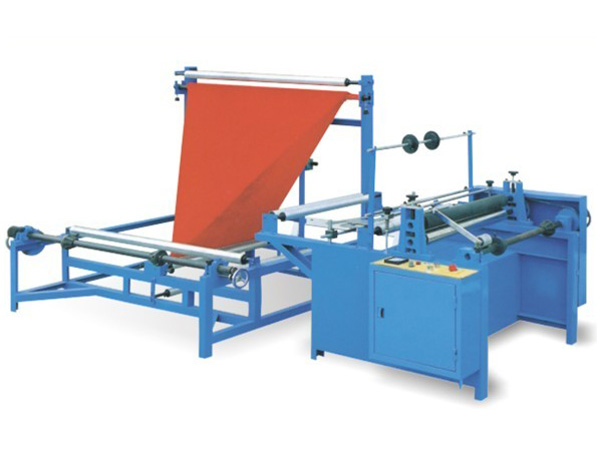

- Slitter Rewinder

The automatic slitter rewinder is a newly designed vertical slitting and rewinding machine. It conducts winding and unwinding operations at the same side. With heavy duty, this product can cut large sized rolled film or paper into small sized ones with multiple blades.

-

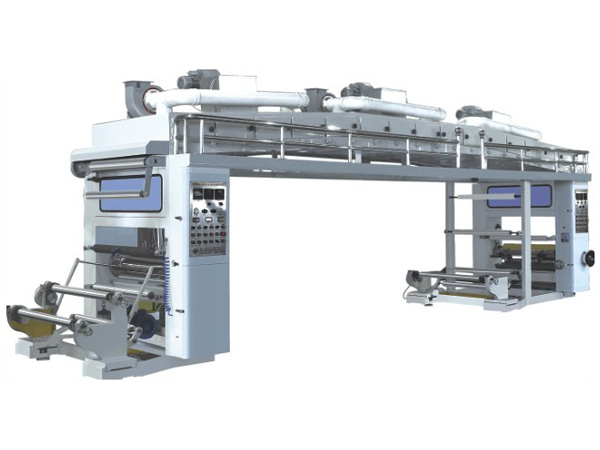

- Film Laminator

At the glue coating section, the anilox roller scraps and coats glue by use of the scraping knife with the glue quantity allowing for free adjustment. Additionally, the rubber roller is pressurized by twin cylinders with the pressure being adjustable.

-

- Plastic Recycling Machine

This range of plastic recycling equipment can replace the plastic grinder or dryer while not changing the color of the raw materials. Having low operation temperature, it rarely destroys the molecular structure and physical properties of raw materials.

-

- Bag Hole Punching Machine

This hole puncher can be manually controlled in a much safer way. The two-way oil channel guarantees steady and reliable operation. The setting of the cutting point of the hydraulic punching unit is convenient, accurate and easy.

Zhejiang Chovyting Machinery Co., Ltd.

Add.: Jiuli Industrial Zone, Ruian City, Zhejiang Province, China

Tel.: +86-577-65188131

Fax: +86-577-65189011