- Home

- Products

- Bag Making Machine

- CWZD-400B+FD, CWZD-500B+FD,CWZD-600B+FD Laminated Bag Making Machine

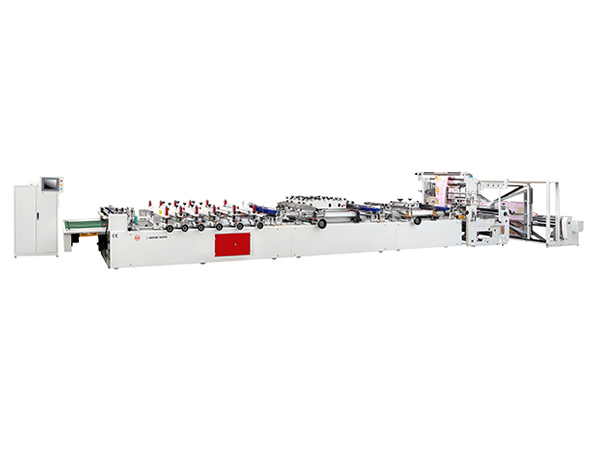

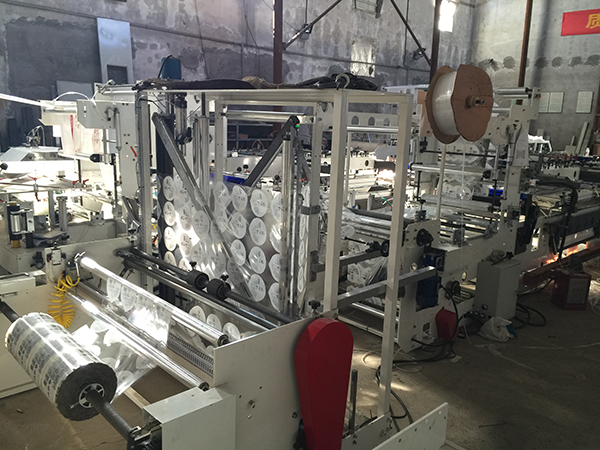

CWZD-400B FD, CWZD-500B FD, CWZD-600B FD Laminated Bag Making Machine

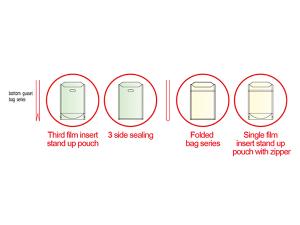

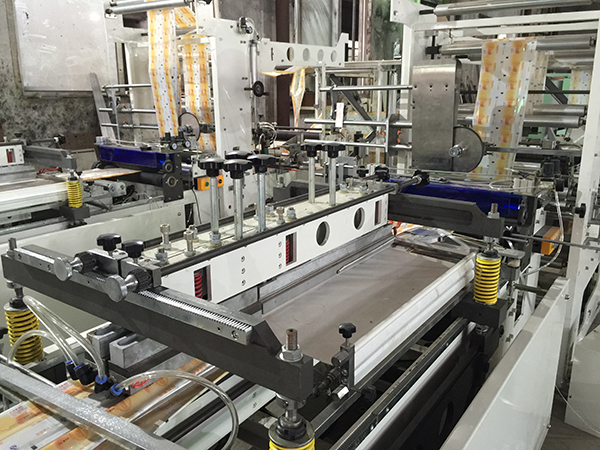

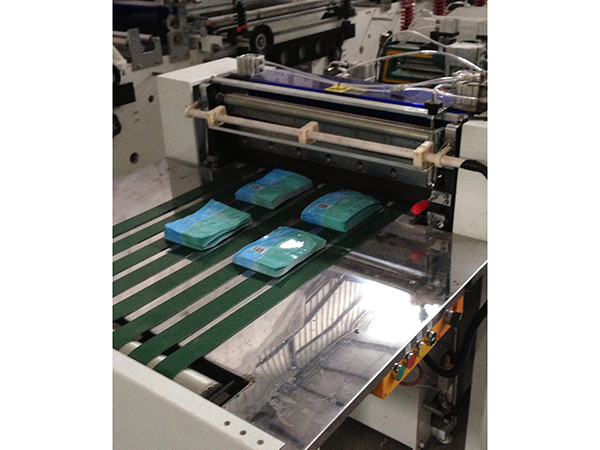

This range of laminated bag making machine is characterized by heavy duty and multiple functions. It comes with a new design for manufacturing laminated bags out of various laminated materials. The product normally produces 3 side sealing bag, stand-up bag as well as zipper bag.

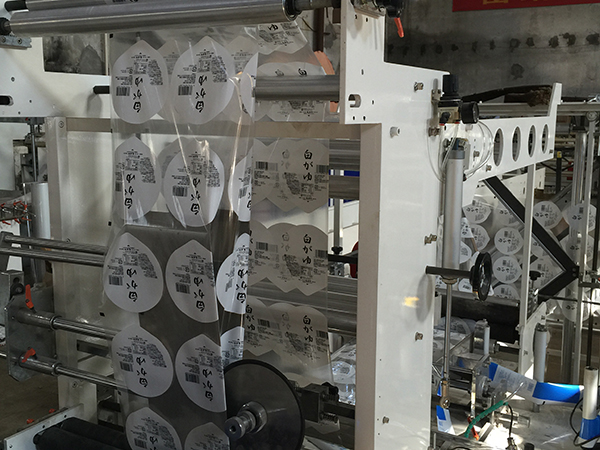

Unlike the CWZD-B model, this range of bag making equipment can make two kinds of stand-up bags. One is made by cutting the bottom and an extra sheet of unprinted film is heat sealed on the bottom. The other comes into being by folding a single sheet film into the bottom without cutting the bottom. The CWZD-B model can only produce the former type of stand-up bag. These bags are mainly applied as food package, like pet food bag. They are well accepted in America.

Features

1. The laminated bag making machine boasts full automation in terms of film folding, punching, bottom gusseting as well as sealing on the bottom to make a complete bag.

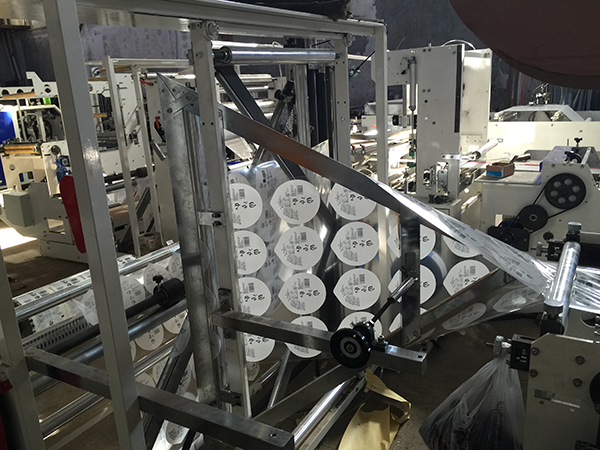

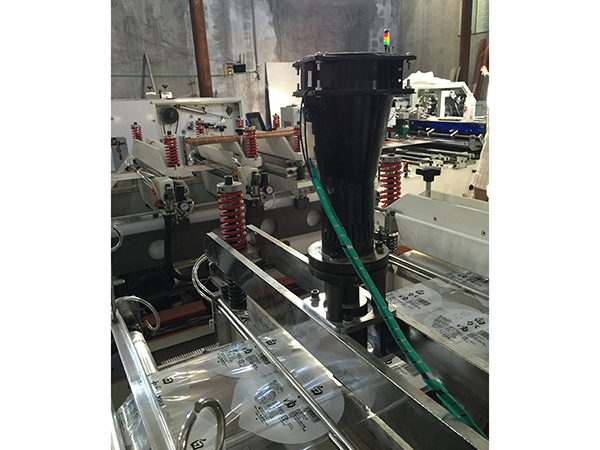

2. It uses a newly designed single sheet film bottom gusseting device.

3. The product also has two Japanese Yaskawa manufactured servo motors as well as driver. The driving system is under the control of PLC made by Japanese Panasonic.

4. It uses the touch screen from Taiwan for presentation of technical parameters.

5. The laminated bag making machine uses a heavy duty bridge type heat sealing construction with high sealing intensity.

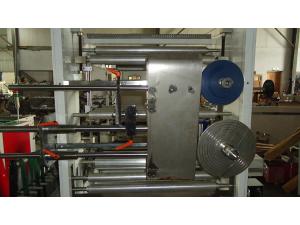

6. Its unwinding device comes with EPC and dual photocell tracking systems. In addition, the unwinding operation is controlled by the automatic tension control mechanism.

7. The product possesses a 6 skip feeding device.

8. It comes with an automatic waste film rewinding equipment.

9. Our laminated bag making device is designed with optional automatic pneumatic material loading device as well as handle punching unit.

| Model | |||

| Unwinding Width | 800mm | 1000mm | 1200mm |

| Pouch Making Length | 70-380mm ×6 ( N≤6 ) | 70-380mm ×6 ( N≤6 ) | 70-380mm ×6 ( N≤6 ) |

| Pouch Making Width | 70-380mm | 70-480mm | 70-580mm |

| Pouch Making Speed | 40-150pcs/min | 40-150pcs/min | 40-150pcs/min |

| Film Feeding Speed | 35m /min | 35m /min | 30m /min |

| Total Power | 38kW | 43kW | 48kW |

| Weight | 3900kg | 4100kg | 4400kg |

| Overall Dimension (L×W×H) | 12300×1750×1800mm | 12300×1950×1900mm | 12300×2050×2000mm |

Note: Attributed to the continuous perfection of existing bag making equipment as well as development of new functions, the appearance, performance characteristics as well as technical parameters may undergo some changes without notice.

Related Names

Stand Up Bag Making Machine | Stand Up Zipper Pouch Machine | Doypack Bag Making Machine

Zhejiang Chovyting Machinery Co., Ltd.

Add.: Jiuli Industrial Zone, Ruian City, Zhejiang Province, China

Tel.: +86-577-65188131

Fax: +86-577-65189011