- Home

- Products

- Auxiliary Machine

- Film Laminator

- Standard Dry Film Laminator

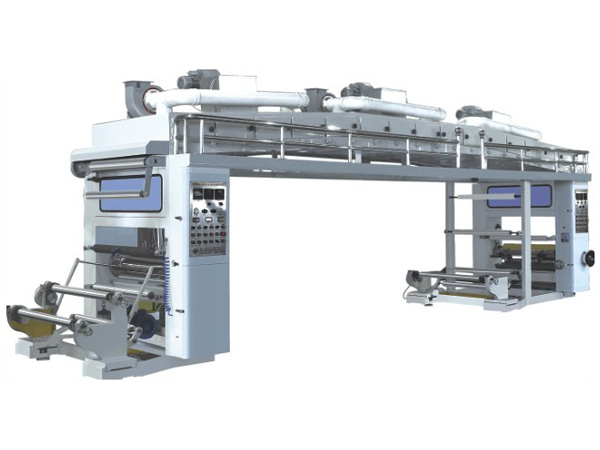

Standard Dry Film Laminator

The standard dry film laminator is excellent for lamination of plastic with plastic, or paper with plastic, etc. It is a good choice for BOPP, PET, CPP, PCVD, aluminized film, aluminum foil as well as paper and compound film having the same properties.

Features

1. The maximum speed of the dry type laminating machine is up to 80m/min.

2. The lamination machine has a 7m long drying tunnel, thus supplying a longer drying time for laminated film. By contrast, the length of the traditional drying tunnel is only 6m.

3. The main driving system chooses AC frequency conversion magnetic powder control. The speed of hot cylinder and anilox roller used for glue coating can be adjusted.

4. At the glue coating section, the anilox roller scraps and coats glue by use of the scraping knife with the glue quantity allowing for free adjustment. Additionally, the rubber roller is pressurized by twin cylinders with the pressure being adjustable.

5. The plastic film laminator uses the single reel discharging device with the photoelectric edge rectifying function. The unwinding operation uses the manual tension control.

6. The product makes use of the coordinated type material collecting device and materials are collected using the torque motor.

7. The lamination equipment is generally used together with the CWZD series laminated bag making machine.

| Model | ||

| Max. Laminating Width | 800mm | 1000mm |

| Laminating Layers | 2 | 2 |

| Laminating Speed | 5-80m/min | 5-80m/min |

| Max. Temperature of Oven | 90°C | 90°C |

| Max. Temperature of Hot Cylinder | 80°C | 80°C |

| Total Power | 52kW | 65kW |

| Weight | 6000kg | 7000kg |

| Overall Dimension(L×W×H)mm | 6500×1800×3600 | 6500×2000×3600 |

Note: The appearance, performance characteristics and technical parameters can be possibly changed without notice, based on our consistent efforts to improve existing products and develop new functions.

Zhejiang Chovyting Machinery Co., Ltd.

Add.: Jiuli Industrial Zone, Ruian City, Zhejiang Province, China

Tel.: +86-577-65188131

Fax: +86-577-65189011